Solutions

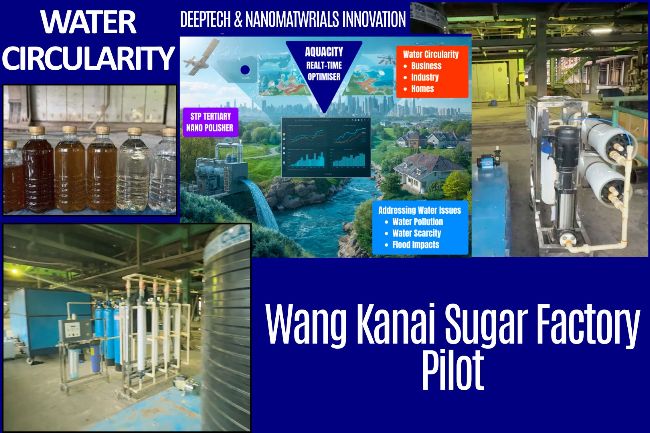

The NANRO industrial water treatment system was integrated with AquaCITY 2.0 – Enviro Watch to deliver intelligent, continuous monitoring and optimisation. AquaCITY aggregates real-time data from IoT sensors, laboratory inputs, and external datasets such as rainfall, weather, and groundwater levels. Machine-learning models analyse trends, forecast future values, and detect anomalies across key parameters, including BOD, COD, heavy metals (lead, mercury, iron, arsenic, chromium), pH, phosphorus, nitrates, flow, FOG, E. coli, total coliforms, and Water Quality Index (WQI). The platform provides live dashboards, KPI tracking for water in/out volumes and recycling efficiency, historical trend analysis, maintenance scheduling, and energy monitoring. This enables operators to optimise treatment performance, anticipate issues, and improve overall system reliability.